News

Energy Management

Environment & Sustainability

Equipment & Systems

Paper

Voith and Koehler Paper to partner on developing decarbonizing solutions

October 11, 2022 By P&PC Staff

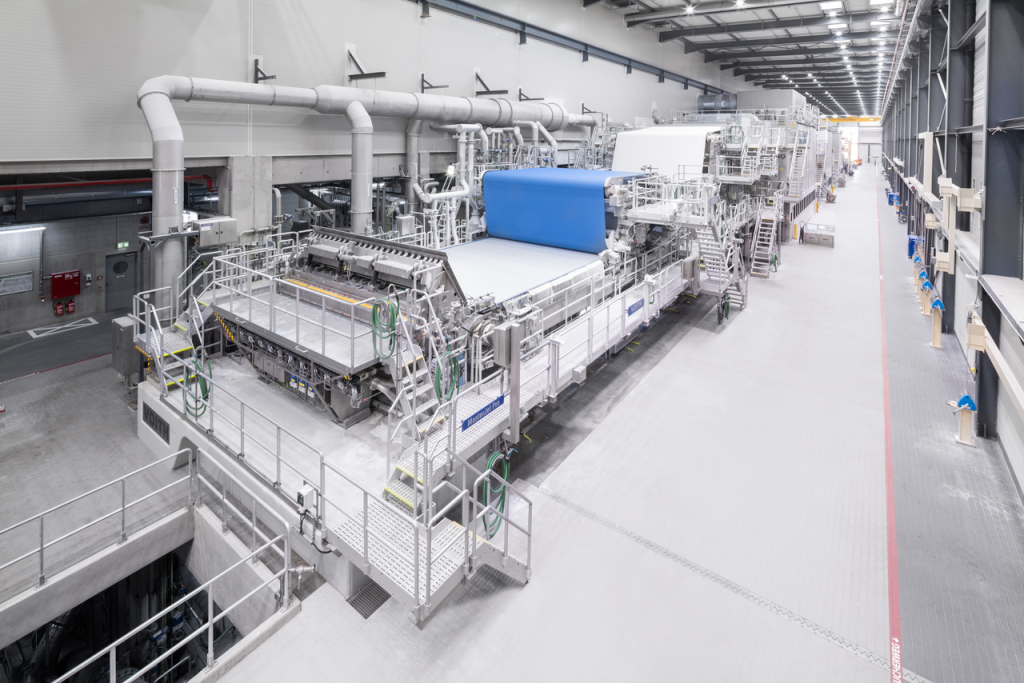

Resource efficiency was at the heart of the project for production line 8. (Photo: Voith)

Resource efficiency was at the heart of the project for production line 8. (Photo: Voith) Voith and Koehler Paper’s pioneering production line 8 in Kehl is a result of their strong business relationship. Both companies have announced that a focus on decarbonization is the next step planned in the development partnership.

A key initiative will be to further optimize the energy efficiency of the Koehler plants. Under this partnership, the Voith-Koehler team will validate alternative energy sources that can serve as future heat sources. Among other things, the focus is on replacing fossil fuels with sustainable CO2-neutral alternatives and retrofitting the production lines accordingly. In this context, contactless drying can be electric or hydrogen-based. Furthermore, an electrified dryer section and heat pumps offer further possibilities for efficiency increase and energy recovery. Biogas obtained from anaerobic wastewater post-treatment can also contribute to the decarbonization of the papermaking process.

“In addition to the many future measures, Voith and Koehler are already working closely together to quickly implement short-term decarbonization measures. To this end, we are developing and installing highly efficient solutions to further reduce CO2 emissions,” said Lada Bemert, vice-president of new business and research at Voith Paper.

Since the delivery of the Voith line in 2019, the 150-meter-long line has been producing sustainable packaging paper at a design speed of 1,500 metres per minute. The heart of the line is a Yankee cylinder with a diameter of over 7.3 meters. The coating machine specifically uses a non-contact, gentle drying process with simultaneous high thermal efficiency, which is achieved by a heat recovery system.

In addition, Voith experts implemented a sustainable water management system on the paper machine designed to reduce fresh water consumption compared to conventional systems. Production line 8 uses exclusively green electricity from the Schluchsee hydroelectric power plant, enabling Koehler Paper to save 45,000 tons of CO2 every year.

Print this page